Combined Heat and Power

FG Wilson CHP Power solutions

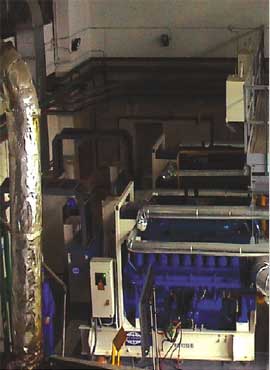

We, in conjunction with FG Wilson, offer on-site solutions for the cogeneration of heat and power using Natural gas and Bio-gas fuelled generating sets.

Our engineers work with you to provide a CHP solution to meet the specific requirements of your application.

A typical CHP solution includes:

- Heat recovery module consisting of:

- Jacket water plate heat exchanger

- Exhaust gas tubular heat exchanger

- Control panel for system monitoring and protection

- Thermostatic exhaust gas by-pass valve with actuator and manual override

- Natural or Bio-gas spark ignited generating set.

- On set monitoring and control.

- Electric motor driven radiator.

- Interconnecting pipework and fittings including pumps and thermostats rated to suit application.

Combined Heat and Power

| Gen Model | PG345B3 | PG450B1 | PG525B1 | PG620B1 | PG750B | PG1080B2 | PG1250B |

|---|---|---|---|---|---|---|---|

| Engine TA-Luft(kW)* | 4006-23TRS1 | 4006-23TRS2 | 4008-30TRS1 | 4008-30TRS2 | 4012TESI | 4016-61TRS1 | 4016E-61TRS |

| Energy in Fuel(kWth) | 820 | 978 | 1119 | 1298 | 1782 | 2288 | 2574 |

| Energy in Power1(kWm) | 322 | 393 | 447 | 536 | 632 | 912 | 1042 |

| Energy in Heat2 - Exhaust(kWth) | 263 | 311 | 350 | 398 | 345 | 539 | 665 |

| Energy in Heat3 - Coolant(kWth) | 190 | 219 | 260 | 290 | 525 | 487 | 584 |

| User Water | Performance of Heat Recovery system is based on 100% continuous operation at test operating conditions and is therefore typical only actual performance is established during detailed design. | ||||||

| Water Flow(kg/h) | 28000 | 28000 | 27540 | 28800 | 30240 | 88200 | 43200 |

| Water Temperature In(°C) | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Water Temperature Out(°C) | 84 | 86.5 | 90 | 90 | 95 | 80 | 95 |

| Water Pressure Inlet(bar) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| System Pressure Drop(bar) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Heat Power Recovered 2 + 3(kW) | 453 | 530 | 600 | 688 | 900 | 1026 | 1249 |

| TOTAL Power Recovered 1 + 2 + 3(kW) | 775 | 923 | 1057 | 1224 | 1532 | 1938 | 2291 |

* All generating sets comply with TA-Luft emissions standards. Heat Balance and Performance based on Natural Gas LHV at 34 MJ/m3 (930 Btu/cu.ft).

CHP Reference

Gostomel Glass factory – Energy Alliance, Ukraine

ENERGY in FUEL (fuel heat of combustion) = 2574kW (100%)

ENERGY in POWER OUTPUT - NETT (Engine shaft power) = 1042kW (40.5%)

INCORPORATING HEAT RECOVERY

ENERGY in EXHAUST GASES using TUBULAR HEAT EXCHANGER Recovered Energy = 665 kW (25.8%)

ENERGY in JACKET WATER using PLATE HEAT EXCHANGER Recovered Energy = 584kW (22.7%)

TOTAL POWER RECOVERED = 2291kW (89%) per unit

TverStekloPlastic Glass Fibre products, Tver City

ENERGY in FUEL (fuel heat of combustion) = 2574kW (100%)

ENERGY in POWER OUTPUT - NETT (Engine shaft power) = 1042kW (40.5%)

INCORPORATING HEAT RECOVERY

ENERGY in EXHAUST GASES using TUBULAR HEAT EXCHANGER Recovered Energy = 665 kW (25.8%)

ENERGY in JACKET WATER using PLATE HEAT EXCHANGER Recovered Energy = 584kW (22.7%)

TOTAL POWER RECOVERED = 2291kW (89%) per unit

Hypermarket “Gorod”, Moscow

ENERGY in FUEL (fuel heat of combustion) = 1795kW (100%)

ENERGY in POWER OUTPUT - NETT (Engine shaft power) = 632kW (35.2%)

INCORPORATING HEAT RECOVERY

ENERGY in EXHAUST GASES using TUBULAR HEAT EXCHANGER Recovered Energy = 365 kW (20.3%)

ENERGY in JACKET WATER using PLATE HEAT EXCHANGER Recovered Energy = 584kW (29.8%)

TOTAL POWER RECOVERED = 1532kW (85.3%) per unit

Skidelskyi Cheese Dairy, Belarus

ENERGY in FUEL (fuel heat of combustion) = 1119kW (100%)

ENERGY in POWER OUTPUT - NETT (Engine shaft power) = 447kW (40.0%)

INCORPORATING HEAT RECOVERY

ENERGY in EXHAUST GASES using TUBULAR HEAT EXCHANGER Recovered Energy = 350kW (31.3%)

ENERGY in JACKET WATER using PLATE HEAT EXCHANGER Recovered Energy = 250kW (22.3%)

TOTAL POWER RECOVERED = 1532kW (93.6%) per unit